July 06, 2025

How Well Do You Know About Nitrile, Latex, Chloroprene & Pvc Gloves?

The main difference of natural rubber, nitrile and chloroprene gloves in terms of their materials, characteristics, protection level as well as usage purpose.

Why is it important for you?

| IF YOU ARE IN A GLOVES BUSINESS | IF YOU ARE THE END USER WHO ARE LOOKING FOR GLOVES |

|

It is essential to understand the differences between these types of gloves before introducing the relevant products to your target market. Consider the scenario where you visit a glove supplier's website and are immediately presented with a list of options, but with minimal information provided. Without a clear understanding of each type, how would you determine which gloves are most suitable to inquire about? |

Imagine standing before a vast array of gloves—how would you determine which type is best suited for your needs? With so many options available, it’s easy to feel overwhelmed. If you're uncertain about which gloves to choose, we recommend taking a few minutes to read through this article. It provides clear explanations to help you understand the differences between glove types. Alternatively, you can skip to the summary section for a quick overview presented in an infographic. To be candid, if I weren’t working in the glove industry myself, I might also struggle to distinguish between the options. Like many, I might have chosen gloves based on packaging design or color, rather than considering the material and its intended use. |

Natural Rubber Gloves (a.k.a Latex Gloves)

Let us begin with natural rubber gloves, which are manufactured from latex. Before proceeding, we would like to clarify an important distinction regarding the term “latex gloves.” This explanation will help you understand why, throughout this discussion, we refer to them as “natural rubber gloves” instead.

Technically speaking, “latex” refers to the material in its liquid form. In contrast, the term “natural rubber” encompasses all materials derived from or containing natural latex—this includes natural rubber latex, synthetic latex, and synthetic rubber formulations that incorporate natural rubber. Therefore, latex and natural rubber represent different physical states of the same base material: latex is the liquid form, while natural rubber is solid.

Rubber gloves are typically produced by a dipping process that uses natural rubber latex. Although the term “latex gloves” is commonly used in the industry, we believe that “natural rubber gloves” is a more accurate and informative term, and thus we have chosen to use it throughout our content.

Materials:

The term “latex” refers to the milky fluid of agricultural origin derived from the sap of the Brazilian rubber tree (Hevea brasiliensis). This substance is used in the production of natural rubber products and coagulates upon exposure to air.

Our natural rubber gloves are manufactured using a high-quality, premium-grade natural latex compound.

Characteristics:

Pros

- Exceptionally soft and flexible, providing a comfortable fit and excellent tactile sensitivity for the user.

- High tensile strength, meaning the gloves can withstand significant stretching and pulling forces. This enhances durability and resistance to tearing, making the gloves tougher and more reliable in demanding applications.

Cons

- Residual proteins in natural latex gloves can cause Type I allergic reactions in individuals who have developed sensitivity to natural latex proteins.

Protection Level:

Pros

- Provides excellent barrier protection against bacteria and viruses

Cons

- Offers limited resistance to oils, fats, and hydrocarbons compared to certain synthetic alternatives.

Usage Area:

General house chores, eg. dish washing, janitorial cleaning, gardening etc.

Nitrile Gloves

Nitrile gloves are available in both disposable and reusable forms. Products such as examination gloves, surgical gloves, and general medical gloves are commonly referred to as nitrile gloves.

Please note that our nitrile gloves are chemical-resistant and differ significantly from standard disposable nitrile gloves in terms of grade and formulation.

For a quick comparison, we have illustrated the key differences in the image below:

|

THICK AND COME IN HAND SPECIFIC |

THIN AND AMBIDEXTROUS

|

Materials:

Nitrile is a synthetic rubber co-polymer composed of acrylonitrile and butadiene.

Our chemical-resistant nitrile gloves are manufactured using a specially formulated acrylonitrile-butadiene compound, designed to enhance durability and chemical protection.

Characteristics:

Pros

- Offers superior durability, providing a longer lifespan compared to natural rubber gloves.

- Does not contain latex proteins, eliminating the risk of developing a Type I latex allergy.

(Please note: While switching to nitrile gloves eliminates the risk of developing a Type I latex allergy, there remains a possibility of developing a Type IV latex allergy.)

Cons

- Exhibits less flexibility than natural rubber gloves.

Protection Level:

Pros

- Demonstrates superior resistance to abrasion, cuts, and punctures compared to natural rubber gloves.

- Offers exceptional protection against a broad spectrum of chemicals, including strong detergents, greases, oils, most solvents, and acids.

Usage Area:

Chemical handling, oil refining, automotive industry, printing industry, agriculture etc.

Neoprene Gloves

Chemical-resistant neoprene gloves provide protection against a wide variety of oils, acids, caustics, and solvents. However, neoprene offers lower resistance to snags, punctures, abrasions, and cuts compared to nitrile or natural rubber.

Materials:

It is a synthetic rubber created through the polymerization of chloroprene, a process in which individual molecules are linked together to form large, multi-unit molecules.

Characteristics:

Pros

- Neoprene offers superior resistance to degradation compared to natural rubber, which results in a longer lifespan for these work gloves.

- Neoprene gloves are chemically inert, making them ideal for withstanding petroleum-based substances such as solvents, oils, and greases.

Protection Level:

Pros

- Exceptional resistance to abrasion.

- Offers good resistance to most solvents, mild acids, oils, and fats.

Cons

- Exhibits limited resistance to strong oxidizing acids, esters, ketones, chlorinated compounds, aromatic hydrocarbons, and nitro hydrocarbons.

- Provides lower resistance to snags, punctures, abrasions, and cuts compared to nitrile or natural rubber.

Usage Area:

Industrial chemical processing, printing industries, oil refineries, automotive paint shop, pesticides handling, agriculture, environmental waste clean up, general maintenance etc.

PVC Gloves

PVC gloves offer protection against concentrated acids and bases, as well as salts, alcohols, peroxides, fats, and water-based solutions, making them ideal for handling objects in wet conditions. Additionally, PVC gloves provide reliable protection against abrasion.

Materials:

PVC, or Polyvinyl Chloride (also known as Vinyl), is a synthetic thermoplastic polymer derived from vinyl chloride, a petroleum-based compound. To be used in glove manufacturing, PVC must be blended with plasticizers, which raises environmental and health concerns.

Characteristics:

Pros

- A type of plastic, PVC is more durable than both natural rubber and neoprene.

- There is no risk of Type I allergy, and Type IV allergies are rare.

Cons

- Being a thermoset resin, it does not offer the same softness and flexibility as elastomers like natural rubber, nitrile, and neoprene.

Protection Level:

Pros

- Provides good abrasion resistance, but is susceptible to cuts and snags.

- Offers excellent grip, even in wet conditions.

- Provides excellent resistance to most aqueous solutions and detergents, and offers better protection against stronger acids and bases compared to natural rubber, nitrile, and neoprene.

Cons

- Offers poor heat resistance and is not recommended for use in high-heat environments.

- Offers limited resistance to organic solvents.

Usage Area:

Commercial fishing, maintenance, mining, fuel oil, mechanic work, construction, petrochemicals

Summary

Understand that some of you might prefer an infographic to have a glance at the differences, here you go

| TYPES OF GLVOES | LATEX GLOVES | NITRILE GLOVES | CHLOROPRENE GLOVES | PVC GLOVES |

| MATERIAL | Latex |

Acrylonitrile Butadiene |

Polychloroprene Rubber |

Polyvinyl Chloride |

|

CHARACTERISTICS |

+ Soft & flexible + High tensile strength - Contain latex proteins (can result in Type I latex allergy) |

+ High durability + Last longer + No latex protein - Lower flexibility |

+ Resist degradation better + Chemically insert to withstand petroleum based mixtures (eg: solvents, oils, greases) |

+ A kind of plastic and more durable than natural rubber and Neoprene. + No concern of Type I allergy and Type IV allergy are rare - Is a thermoset resin it does not match the softness and flexibility of elastomer (Natural Rubber, Nitrile & Neoprene) |

|

PROTECTION LEVEL |

+ Good performance barrier to virus and bacteria - Poor oil, fat & hydrocarbon resistance |

+ Superior resistance to abrasion, cut & puncture + Protection against wide range chemicals |

+ Excellent abrasion resistance + Good resistance to most solvents, mild acids, oils & fat |

+ Offers good abrasion resistance, but susceptible to cuts and snags. + Provide great grip even in wet condition. + Excellent against most aqueous solutions, detergents and good in stronger acids and bases compare to natural rubber, nitrile and neoprene. |

|

USAGE AREAS |

General house chores, dishwashing, janitorial cleaning |

Chemical handling, oil refining, agriculture |

Industrial chemical processing, oil refineries, printing industries |

Commercial fishing, maintenance, mining, fuel oil, mechanic work, construction, petrochemicals |

Both nitrile and chloroprene gloves are suitable for chemical handling; however, the choice ultimately depends on factors such as the type of chemicals being handled, the duration of exposure, and the specific tasks being performed.

You may be wondering, how do I determine which gloves are best suited for my needs? Is there a way to guide my decision?

The answer is yes. The key indicator you should look for is the glove performance pictogram.

Often, you'll notice stamps or markings on the gloves themselves. These serve as important indicators of the glove's performance and can help guide your decision.

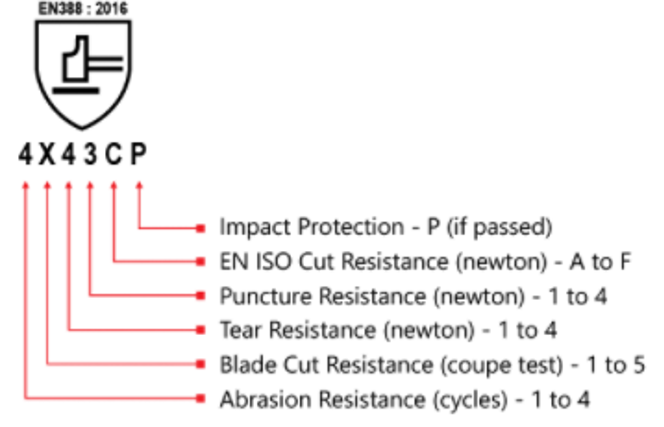

How to read the glove performance of EN388?

EN388 is the European standard used to assess mechanical risks for hand protection. The performance pictogram evaluates gloves based on four key aspects: abrasion resistance, blade cut resistance, tearing strength, and puncture resistance.

To determine if a glove is suitable for your needs, it's important to consider not only the material of the glove but also these four aspects to identify which ones should be prioritized based on your specific usage.

For instance, if abrasion resistance is your primary concern, you should compare the abrasion resistance ratings of different gloves. A glove with an abrasion resistance level of 4 will outperform one with a level of 2 in terms of durability.

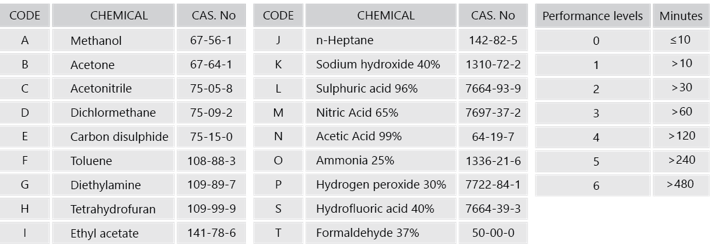

How to read the glove performance of EN374?

This standard specifies the capability of gloves to protect the user from dangerous chemicals and/or micro-organisms.

PERMEATION

Permeation is the measure of the chemical substance penetration of the protective glove. A protective glove can be permeated within seconds. It is therefore necessary to measure breakthrough times for the chemical to come in contact with the skin. Each chemical tested is classified in terms of breakthrough time performance as below table:

Minimum breakthrough times for a Type A glove is 30 mins (Level 2) against minimum 6 chemicals of the chemical list. |

Minimum breakthrough times for a Type B glove is 30 mins (Level 2) against minimum 3 chemicals of the chemical list. |

Minimum breakthrough times for a Type C glove is 10 mins (Level 1) against 1 chemical of the chemical list. |

That being said, it’s often difficult to determine which glove is superior, as different manufacturers use distinct formulations when producing their gloves. Therefore, making a decision solely based on the material type may not be the best approach.

It's always advisable to consult with glove suppliers or vendors, especially if you're handling specific chemicals or working in specialized environments.

Our experts are here to help you select the right gloves to ensure your employees stay protected.

www.sumirubber.com | +604-4213121 | sumirubbermalaysia@srim.com.my

Recent Tips

April 14, 2025

Select The Right Glove For The Right Job

REUSABLE NITRILE GLOVES

REUSABLE NITRILE GLOVES DISPOSABLE NITRILE GLOVES

DISPOSABLE NITRILE GLOVES